Tailored refractory solutions enhance industrial efficiency by precisely addressing extreme thermal and mechanical challenges. Selecting materials that match specific operational demands improves durability and reduces downtime. By combining innovation with proven expertise, these customized products ensure optimal performance across sectors like metallurgy, petrochemistry, and waste treatment—delivering lasting protection and cost-effective maintenance for critical high-temperature processes.

Understanding Refractory Solutions in Industry Applications

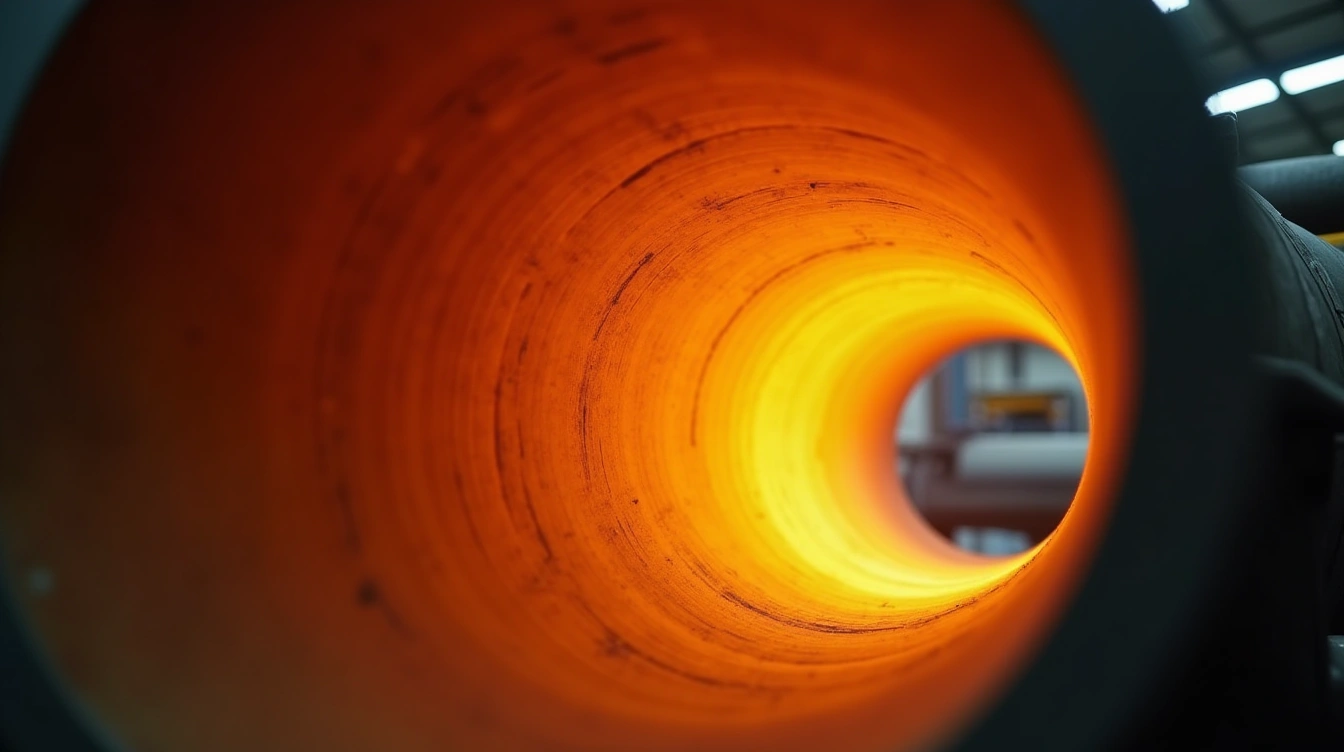

MXS Refractories emphasizes the critical role of heat resistant materials, thermal insulation products, and high-temperature linings in industrial processes. These solutions are essential for maintaining safety, efficiency, and longevity of equipment subjected to extreme conditions. Refractory materials enable industries like metallurgy, waste energy recovery, and petrochemicals to operate reliably under high temperatures, protecting structures from thermal shock and corrosion.

Topic to read : Unlocking the secrets to exceptional floor cleaning services

Industries utilize a diverse range of refractory systems tailored to specific needs. For example, steelmaking requires durable, wear-resistant castables, while glass furnaces demand heat-insulating linings. Advanced refractory solutions also provide environmental benefits by reducing energy consumption and emissions.

Choosing high-quality, innovative refractory systems improves operational efficiency, reduces downtime, and extends equipment lifespan—key concerns for industrial operators. mxs-refractories.com offers tailored solutions that encompass product customization, technical support, and project supervision. This focus on personalized service ensures that clients achieve optimal performance and safety across their high-temperature applications. You can view more details on this page: mxs-refractories.com.

Topic to read : Unlocking success: digital transformation strategies for uk businesses to elevate their services

Types of Refractory Materials and Their Industry Uses

Basic Refractory Materials and Selection Criteria

Practical selection of refractory material types begins with analysing temperature, chemical exposure, and required wear-resistant castables performance. Alumina, magnesia, and silica represent core heat resistant materials in the metallurgical refractory applications sector. High alumina bricks are known for high-temperature stability and frequent use in high-temperature linings for steel industry linings. Proper material choice increases refractory solution benefits—optimal thermal insulation products can dramatically increase operational efficiency.

Advanced Refractory Products for Steel and Non-Ferrous Industries

Steel mills and non-ferrous plants rely on refractory material types able to endure intense thermal cycling, abrasion, and chemical-resistant refractory linings. Wear-resistant castables, including specialized refractory castable mixes, are applied for kiln lining solutions and critical furnace zones. Ceramics and silicon carbide alternatives bolster thermal shock resistant materials and enable extended refractory durability. Ceramic fiber insulation is favoured for secondary linings, minimizing heat loss and supporting thermal efficiency improvement.

Innovative Refractory Coatings and Insulation Technologies

Continuous innovation delivers durable refractory coatings using ceramic fiber insulation, forming effective heat containment solutions for sectors like glass, cement, and petrochemicals. By integrating refractory technology advancements with tailored heat protection systems, customized refractory engineering enables new standards in refractory product performance. Robust industrial furnace coatings sustain thermal barriers—ensuring productivity, efficiency, and compliance with evolving industry requirements.

Engineering, Installation, and Maintenance of Refractory Systems

Custom Solution Design and Industry-Specific Considerations

Custom refractory engineering begins with in-depth analysis of operational conditions. Refractory material types, including ceramic fiber insulation, high alumina bricks, and wear-resistant castables, are matched to process needs—whether for steel industry linings, cement kiln refractory solutions, or glass furnace insulation. Selection of thermal insulation products and heat resistant materials considers not just temperature, but also chemical exposure and mechanical wear. For metallurgical refractory applications, tailored heat protection systems may prioritize thermal shock resistant materials and chemical-resistant refractory linings. This ensures high-temperature linings deliver optimal refractory product performance for each facility.

Best Practices for Refractory Installation and Lifespan Extension

Effective refractory installation techniques require precise mixing of refractory castable mixes, accurate positioning of insulating fire bricks, and professional application of refractory mortar options. Kiln lining solutions can benefit from modular refractory components, while energy-efficient refractory designs reduce operational costs. Installation adheres to strict standards, promoting refractory solution benefits such as extended refractory durability and improved refractory solution cost savings. Regular repair and maintenance of refractories—using compatible refractory products for incinerators, boilers, or power plants—mitigates wear and chemical attack, maximizing refractory lifespan extension.

Monitoring, Testing, and Troubleshooting Refractory Performance

Continuous refractory performance monitoring and refractory lining testing detect issues early. Techniques include refractory inspection methods, refractory failure analysis, and thermal efficiency improvement assessments. Robust refractory system optimization, adapted with refractory technology advancements, refines refractory solution design process for increasing refractory service life enhancement and rapid troubleshooting—minimizing downtime and enhancing refractory solution integration.

Industry Leaders and Case Studies in Refractory Solutions

Saint-Gobain sets standards with refractory solution case studies demonstrating advanced heat resistant materials across heavy sectors. Their engineered thermal insulation products—like the NORFLOW® castables—empower users to install high-performance high-temperature linings efficiently without specialized equipment. Consistent refractory product performance under extreme thermal and mechanical stress is a hallmark, evident in blast furnace linings, aluminium reduction cell materials, and environmental applications such as waste-to-energy and carbon black production.

Trent Refractories’ dominance in refractory innovation is seen through their bespoke refractory engineering for steelmaking and foundries. Their in-house design and manufacturing create precast shapes, EAF Roofs & Deltas, and custom linings that address varying needs for wear-resistant castables, refractory castable mixes, and modular refractory components. Technical collaboration gives rapid, tailored refractory lining solutions. Attention to high alumina bricks and insulating fire bricks ensures thermal shock resistant materials and energy-efficient refractory designs are always available, fitting ongoing refractory industry trends for durability and optimization.

Insertec stands out with a focus on sustainable refractory solutions for foundries and industrial furnaces. Through refractory system optimization and innovative refractory technology advancements, they integrate chemical-resistant refractory linings like Silicast AL to maximize material lifespan. Their mix of testing—porosity analysis, exothermic control—supports consistent refractory solution benefits and longevity, reinforcing reliability in refractory material types across metallurgical and glass-making industries.

Advanced Refractory Solutions: Product Innovations & Industry Applications

Heat resistant materials are fundamental to heavy industry. Selecting the right refractory material types enhances safety and boosts thermal efficiency. Saint-Gobain Performance Ceramics & Refractories engineers high-performance refractory materials with industry-specific durability. For instance, NORFLOW® castables bring thermal insulation products together with straightforward installation—engineered for industries demanding frequent maintenance but minimal downtime. Their blast furnace linings for steelmaking demonstrate the benefits of custom refractory engineering by optimizing key zones from throat to hearth, extending facility lifespan.

Trent Refractories, recognized for its bespoke solutions and rapid response times, excels in wear-resistant castables and modular refractory components for furnaces and ladles. Their expertise ensures kiln lining solutions meet operational demands, whether through quick delivery of standard bricks or full customization for EAF Roof Deltas. Each product is designed to maximize thermal efficiency improvement and resilience under high-load, high-abrasion scenarios.

Insertec advances the field with continuous R&D, offering metallurgical refractory applications for diverse furnace conditions. Their ceramic fiber insulation minimizes heat loss and improves overall energy use. The company’s integrated laboratory focuses on refractory lining testing and adapting materials, delivering better longevity and energy-efficient refractory designs that address evolving environmental and safety criteria for the industry.